Maschinen- und Anlagenbau

von Stahl- und Anlagenbau Schädlich GmbH in Stützengrün

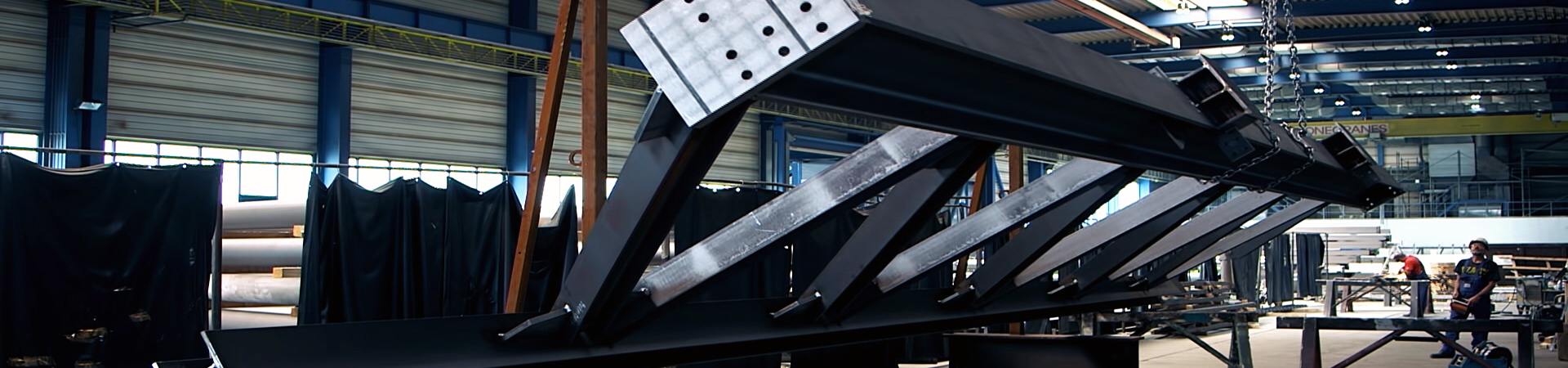

Anlagentechnischer Stahlbau mit mechanischer Großteilebearbeitung (Stahlbaukonstruktionen) bildet mit dem Bereich Maschinen- und Anlagenbau einen weiteren Schwerpunkt im Rahmen unserer Leistungen.

Die moderne Fertigung im Sektor der Großzerspanung wird in der Arbeitsvorbereitung maßgeblich durch moderne CAD/CAM-Systeme unterstützt. Mit insgesamt vier CNC-Bohrwerken mit unterschiedlichen Einsatzkriterien können Baugruppen bis zu 50 to Gewicht, einer zu bearbeitenden Länge von 20 m und einer Höhe von 5 m spanend bearbeitet werden.

Konstruktion und Fertigung mit Präzision in Perfektion

Wir sind in der Lage, die entsprechenden Konstruktionsteile aus Stahl passend vorzufertigen. Bleche werden mittels Brennschneiden, bei kleineren Blechdicken über Laser und Scheren zugeschnitten. Sie können bis zu einer Dicke von 20 mm abgekantet und bis zu 50 mm dick rund oder konisch gewalzt werden. Die so vorbereiteten Bauteile werden mit unseren Hochleistungsschweißverfahren – insbesondere dem UP-Schweißen – gefügt. Korrosionsschutz und ein vorschriftenkonformer Farbschichtenaufbau werden in unseren Betriebseinrichtungen fachkompetent realisiert.

Zu unseren Auftraggebern zählen Kunden aus z.B. dem Maschinenbau, dem Fahrzeugbau, dem Kranbau, der Erdölfördertechnik sowie der Windkrafttechnik.

Fragen Sie uns – Von Stahl- und Anlagenbau Schädlich erhalten Sie alle Leistungen aus einer Hand!